Services

SAFE MECHANICAL DESIGN, OUR "CORE-BUSINESS"

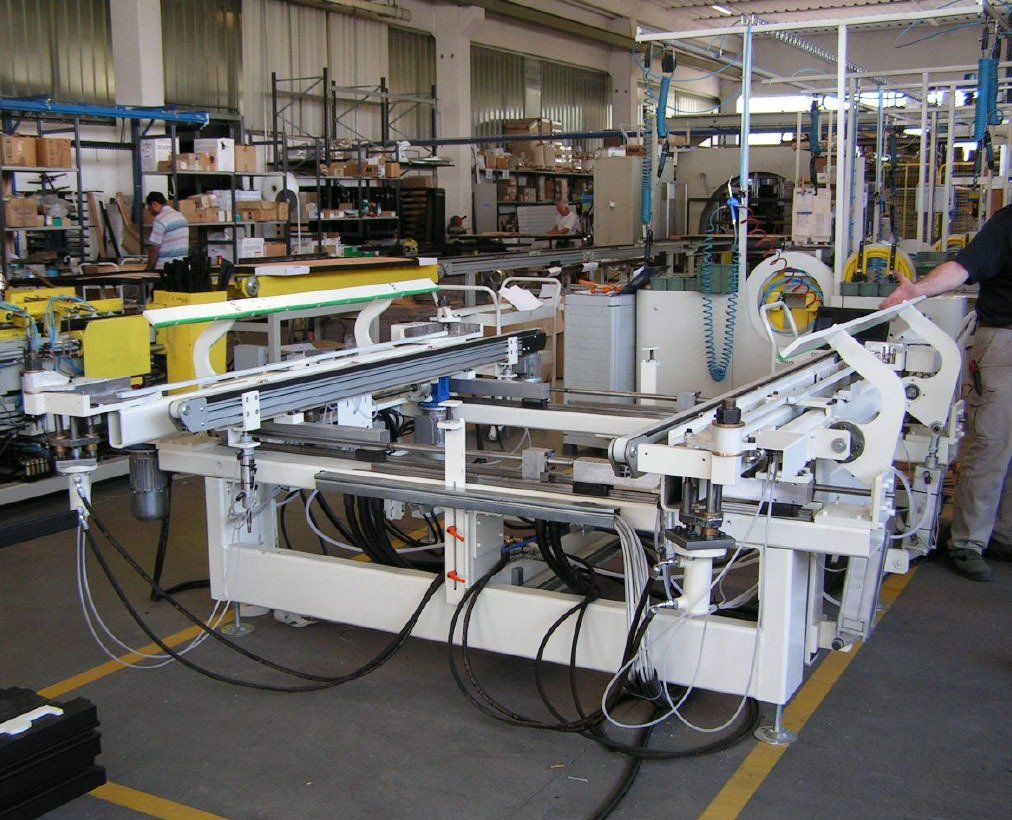

Feasibility studies, mechanical design of optional units, series machines, special machines and industrial plants are just some of the services offered in the field of industrial mechanical design: • we take care of the functionality of the machines and equipment we design; • we carry out the sizing and have the skills and experience necessary to choose the best components based on the quality / price ratio for the required application; • we support the end user, simulating the use of the machinery and verifying ergonomics; • we seek aesthetics for impactful and captivating solutions; • we automate your equipment, proposing robotic solutions not to replace the worker but to relieve the worker from heavy, tiring or high-risk tasks; • above all, we never neglect the main aspect for us: safety. We verify compliance with sector regulations, perform structural calculation and fatigue analysis as often as necessary, complete the design with risk analysis and the preparation of all the necessary documentation for the construction of the technical file. and CE certification. In our small way, we always strive to offer a quality service and give great help to our customers. Design outsourcing is the possibility of a gradual approach to test its feasibility; with minimal investments and without any risk; it is the possibility of verifying if it is the right solution for your company, by getting to know us.

WE DEVELOP YOUR IDEAS

From the very first meetings, we participate to welcome your ideas, sharing needs, doubts and problems: we elaborate the project specifications together ... then we immediately begin to design and develop the ideas with 3D CAD modeling software, generally SolidWorks or Inventor.

OUR CONCEPT OF "INDUSTRIAL DESIGN"

Search for creative and impactful solutions that reconcile functionality and aesthetics, through the application of Design Thinking to solve complex problems, using a vision and creative management with the needs of the customer, the market and production technologies at the center. Studio Pro.De.Co. is able to offer its customers "project technicians" able to operate competently in all phases of design and development of industrial products and to act as a link between the moment of conception and that of production, covering the various activities ranging from product design to large-scale production, including in the field of visual and multimedia communication. Intelligence and creative sensitivity with a broad vision of complex problems and the consequent transformative processes will ensure that the company that relies on our structure can avail itself of valid support; the vast experience gained, even in specific fields such as the design and production of die-cast articles in metal and plastic materials or made by blanking, for the world of clothing and in the interior design sector, can validly support the customer in the development of new products. Thanks to collaborations with companies and research laboratories, Studio Pro.De.Co. supports the development of new products, technologies and innovative applications. To complete the services offered in the design, Studio Pro.De.Co. also equipped itself with cutting-edge tools for the creation of prototypes using 3D printing for laser stereolithography.

SAFETY OF MACHINES AND "CE" MARKING

Machine Safety is one of the cornerstones of our studio, thanks to years of experience in the sector, direct knowledge of problems related to both the design and use of machinery, and the continuous updating of our technicians which has allowed us to acquire competence in the Machinery Directive 2006/42 / EC and in the European Product Directives. We support our customers in the creation of all the documentation accompanying the project, necessary for the correct and conscious CE marking and the establishment of the Technical Construction File: • Use and Maintenance Manual • Exploded views and Spare Parts Manual, including interactive and multimedia • Evaluation of the compliance with the Essential Health and Safety Requirements according to the Machinery Directive • Risk Analysis by applying the hybrid method of the UNI ISO TR 14121-2: 2013 standard • Performance Level Analysis according to the EN ISO 13849-1 standard.

SPECIFIC ADVICE

REGULATION OF EXISTING MACHINES AND PLANTS INDUSTRY 4.0: The technicians of Studio Pro.De.Co. are able to carry out: technical appraisals, sworn or sworn where necessary (for leasing, contributions, tenders, ...); appraisals of parties in legal cases (CTP); sworn appraisals for the INDUSTRY 4.0 national plan; appraisals for the determination of the value of machines and plants; product conformity appraisals. Eng. Davide Baldini, owner of the firm, is accredited as a technical expert (CTU) at the Court of Siena. VERIFICATION OF STRUCTURAL INTEGRITY BY THE "EXPERT ENGINEER" OBLIGATION TO VERIFY THE STRUCTURAL INTEGRITY (OR "TEN-YEAR VERIFICATION") OF THE LIFTING EQUIPMENT ADDITIONAL SURVEY OR TWENTY-YEAR VERIFICATION OF THE LIFTING-CHECKING EQUIPMENT ON EARTH VERIFICATION earthing systems; checks on protective devices against atmospheric discharges; checks on electrical systems in places with danger of explosion; Extraordinary grounding checks.

TRAINING ACTIVITY

Studio Pro.De.Co. has always organized Training Courses to support consultancy activities, to implement the services offered and to spread the culture of safety. The firm, through its Form & Co training center (affiliated with ANFOS as a territorial center), offers teaching activities and organization of courses in compliance with the provisions of Legislative Decree 81/2008 and subsequent amendments, in particular as regards: • l '' safe use of Machines and Equipment (forklifts, bridge cranes, MEWPs, earth-moving machines, ...) • courses on Basic and Specific Safety for RSPP, workers, RLS; • courses for Firefighters and First Aid; • Professional refresher courses (Technical Design, quality control,…).